Tank Sizing

Select a type of tank to calculate the model needed for your installation:

HVAC Expansion

Close

A properly sized tank will accommodate the change in system fluid volume during heating or cooling cycle without allowing the system to exceed critical pressure relief valve limits.

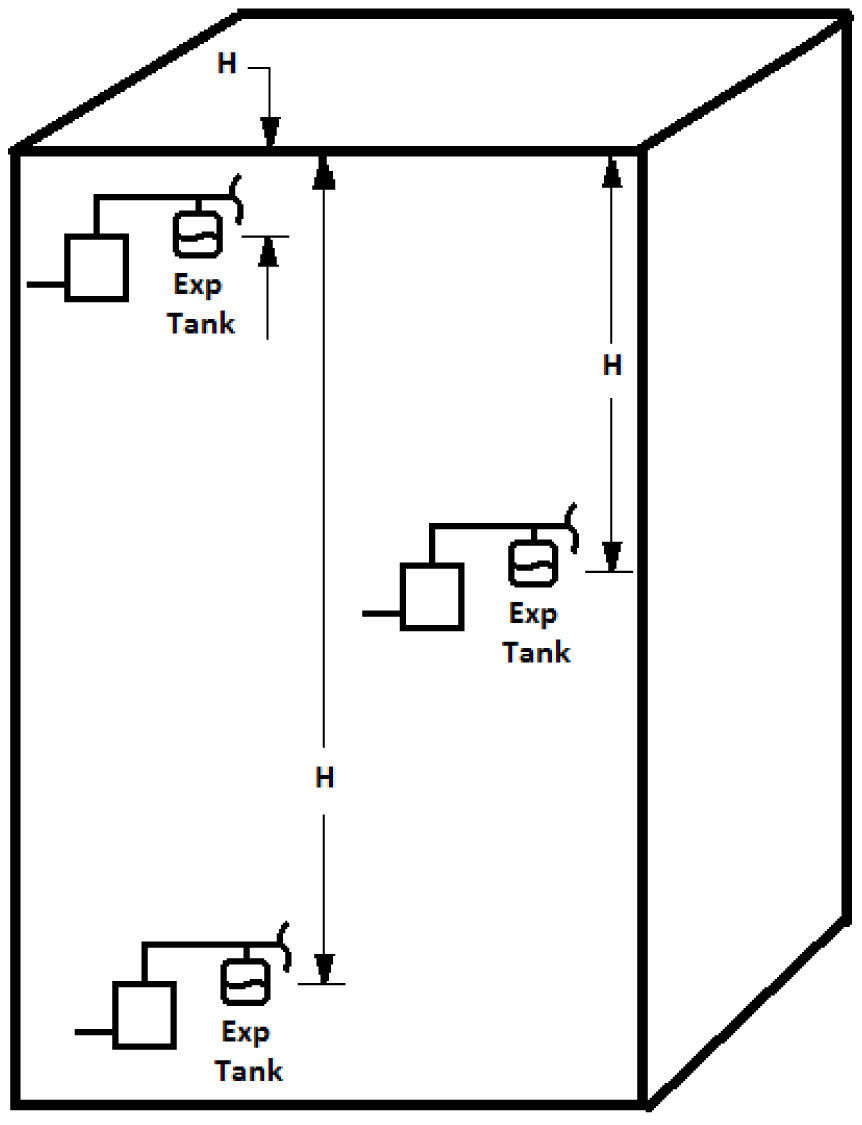

HVAC Expansion Tank

Expansion tanks are required in a closed loop heating or chilled water HVAC system to absorb the expanding fluid and limit the pressure within a heating or cooling system.A properly sized tank will accommodate the change in system fluid volume during heating or cooling cycle without allowing the system to exceed critical pressure relief valve limits.

Compression Conversion

Close

Convert a Compression Tank

Convert a compression style expansion tank into a bladder or diaphragm expansion tank.

Domestic Hot Water

Close

A properly sized thermal expansion tank will accommodate this additional volume of water created through expansion during the heating cycle, and control the system pressure increases, keeping pressures from reaching critical safety relief limits.

Domestic Hot Water Tank

Thermal expansion tanks are designed for pressure control in a potable water system. The building's water heater or water heating system typically creates thermally expanded water.A properly sized thermal expansion tank will accommodate this additional volume of water created through expansion during the heating cycle, and control the system pressure increases, keeping pressures from reaching critical safety relief limits.

Well & Pressure Booster

Close

Properly sized, these tanks provide drawdown water used to supply water for small demand loads, keeping the pumps off until needed. Additionally, these tanks can be applied to reduce harmful surge and water hammer pressure spikes.

Well & Pressure Booster Tank

Hydro-pneumatic tanks are vessels that store water for a municipal well system or pressure boosting station.Properly sized, these tanks provide drawdown water used to supply water for small demand loads, keeping the pumps off until needed. Additionally, these tanks can be applied to reduce harmful surge and water hammer pressure spikes.

Buffer

Close

A properly sized tank adds the necessary water volume to "buffer" the system to dampen fast transitions and eliminate short cycling.

Buffer Tank

Buffer tanks are required for systems with insufficient water volume capacity to eliminate short cycling of chiller or boiler components, poor temperature control, and erratic system operation.A properly sized tank adds the necessary water volume to "buffer" the system to dampen fast transitions and eliminate short cycling.

Flash

Close

Flash Tank

Flash tanks are designed for systems that require flashing of high pressure condensate into steam for low pressure heating supply mains, and to reduce the cool low pressure steam before it is returned to the boiler, condensate receiver, or discharged into sewer.Critical Sizing - HVAC Expansion

Critical Sizing - Convert A Compression Tank

Select volume calculation method:

Select volume calculation method:

Critical Sizing - Domestic Hot Water

Critical Sizing - Well & Pressure Booster

Critical Sizing - Buffer

Select volume calculation method:

Draw-down Estimator

Close

Consult motor manufacturer.

Rule-of-thumb use:

Up to 3/4 hp - use 1 min.

1-3 hp - use 2 min.

Over 3 hp - use 3 min.

For VHD motors, consult factory'

Rule-of-thumb use:

Up to 3/4 hp - use 1 min.

1-3 hp - use 2 min.

Over 3 hp - use 3 min.

For VHD motors, consult factory'

System Volume:

Flash Sizing

Calculated Critical Sizing

Required Tank Volume

Tank Volume

Bladder: gallons Diaphragm: gallons Compression: gallons

Recommended Products

Back to CalculatorCalculated Critical Sizing

Total Disengaging Area

Recommended Products

Flash Horizontal

Flash Vertical

Request Quote - Estimate Freight

Estimated Freight Cost

$77.49 USD

Order Submitted

Thank You

Your order has been submitted.